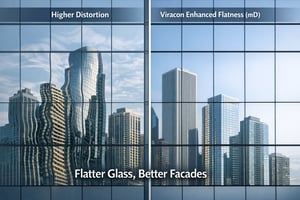

Flatter Glass, Better Facades: What Viracon’s New Millidiopter Specification Means for Your Projects

Architects spend countless hours refining elevations, aligning mullions, and tuning glass...

If you’ve ever stood across the street from a “neutral” glass façade and noticed 3 or 4 slightly different shades staring back at you, you already know the problem this article is about.

If you’ve ever stood across the street from a “neutral” glass façade and noticed 3 or 4 slightly different shades staring back at you, you already know the problem this article is about.

On paper, the glass is often in spec. In the field, it can read as a patchwork.

Viracon’s Enhanced Coating Delta E Collection is one way to close that gap—tightening color control so façades read as one coherent surface instead of a mix of panels that all technically pass ASTM, but don’t quite match your rendering.

This post walks through what that means, in plain language, and when it’s worth considering on your projects.

Most conversations about glass focus on:

All important. But there’s another question that usually surfaces later, often at mockup stage or after installation:

“Why doesn’t this all look the same?”

Viracon’s Enhanced Delta E Coating Collection exists to answer that question with a measurable, project‑level standard for color consistency—not just a coating target on paper.

You can spend a lot of time talking about CIELAB, L*a*b*, and color spaces. For most project teams, you don’t need to.

Here’s the simple version:

The catch:

On neutral, higher‑transission Low‑E coatings—the kind used on many modern commercial, institutional, and campus buildings—you can still see real variation at ΔE 4.0, especially across a big elevation.

So: “in spec” doesn’t always feel “right” to the client standing in the plaza.

Most of the industry still works to the ASTM C1376 tolerance:

Most of the industry still works to the ASTM C1376 tolerance:

Viracon’s Enhanced Delta E Collection tightens that significantly:

That’s about half the typical tolerance.

In practical terms:

Think of it as narrowing the window so what you see on the building actually looks like what you signed off on in the mockup and rendering.

This isn’t just a spec line—it’s a process:

This isn’t just a spec line—it’s a process:

The net effect: there’s a measurable, traceable basis for saying, “This glass was produced and delivered to an average ΔE of 2.0 or less.”

Not every coating needs this level of control.

Not every coating needs this level of control.

You notice color variation most on:

In Martineau & Co’s work across the Northeast that often means:

On those projects, an elevation that’s technically “in spec” at ΔE 4.0 can still read as multiple shades. Tightening to a 2.0 average keeps most variation in a range that people simply don’t notice in everyday viewing.

(For a broader look at the types of projects we support, you can always visit mandcomp.com and explore the project and partner examples there.)

Different stakeholders feel this in different ways:

That doesn’t remove every disagreement, but it gives everyone something concrete to stand on.

Enhanced Delta E is a situational tool, not something to bolt onto every storefront or back‑of‑house elevation.

It tends to deliver the most value on:

In those contexts, the premium for tighter color control can be cheap insurance compared to the cost—financial and reputational—of a façade that looks subtly “off” for decades.

You don’t need to invent new language from scratch.

In the spec, it can be as straightforward as:

“Glass fabricator shall provide Viracon Enhanced Delta E Coating Collection with average reflected ΔE ≤ 2.0 to ASTM C1376, verified by Viracon’s Certificate of Acceptance (COA).”

Behind that single line lives:

You’re essentially anchoring your project to Viracon’s tighter internal standard instead of relying solely on the broader ASTM tolerance.

Locally, our role at Martineau & Co is to help you decide:

We can help:

Our project mix spans healthcare, education, civic and institutional, commercial, cultural, and more across the New York–Philadelphia corridor. Enhanced Delta E is one of the tools we use selectively in that mix—not a one‑size‑fits‑all requirement.

If you’ve had a project where neutral glass didn’t look as consistent as you expected—or if you’re working on a new façade where appearance will be scrutinized—it might be worth a closer look.

If you share:

we can come back with a quick recommendation on whether Viracon’s Enhanced Delta E Collection would genuinely reduce your risk or if your standard spec is already appropriate.

That’s what MCo Insights is for: taking tools like this out of the brochure and into the reality of the wide range of projects we support across the Northeast—so your façades look the way you intended, not just the way the numbers read on paper.

Architects spend countless hours refining elevations, aligning mullions, and tuning glass...

2024 Project Insight Viracon started the new year with a bang, diving into several groundbreaking...

Many architects, consultants, and owners across the Northeast are already familiar with Viracon’s...